In Thermal Spray the process the equipments process parameters are carefully controlled. Normally the resulting coating is then evaluated in the lab, microstructure, adhesion, cohesion etc. The question of exactly what caused a specific result is not always easy to answer.

This series of equipment we have developed gives the possibility measure and monitor parameters on the rotating sprayed part and this is done during the complete duration of the coating process. These parameters can be:

• Substrate temperature

• Displacement

• Curvature

• Coating thickness

• Strain

This gives the means to sort out individual characteristics and aid in the task of answering what caused what.

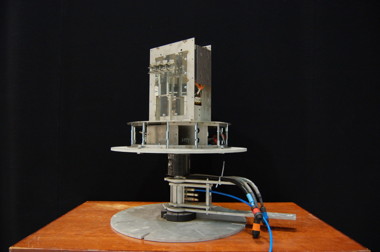

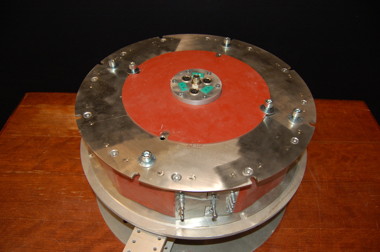

The equipment is a module based telemetry system consisting of spray sample fixtures, Data acquisition system, media supply modules (cooling water, air and electricity), WiFi data transfer and computers with software to sample, save and present data.

Data are acquired and saved in real time before, during and after the spray process. Virtually any type of sensor can, with the proper signal conditioning, be implemented in this system.

• Laser sensors for displacement, distance and thickness measurements

• Pyrometers and thermo couplers for temperature

One of the equipments gives the possibility, by the means of closed loop controlled electrical heaters , to very precisely control the substrate temperature in the range of 20-600 °C. This enables evaluation of the, in thermal spray, very important parameter of

preheating the substrate to be coated.

A number of different preheating temperatures can be tested and later evaluated against coating properties like adhesion or porosity.

For more information:

- 1000001248.mp4 43.3 MB

- 1000001249.mp4 19.9 MB

- 1000001258.mp4 182.5 MB

- 40 mm pistons HVAF download.mp4 63.6 MB

- Control TS Presentation.ppsx 4.9 MB

- englishpump.pdf 63.8 MB