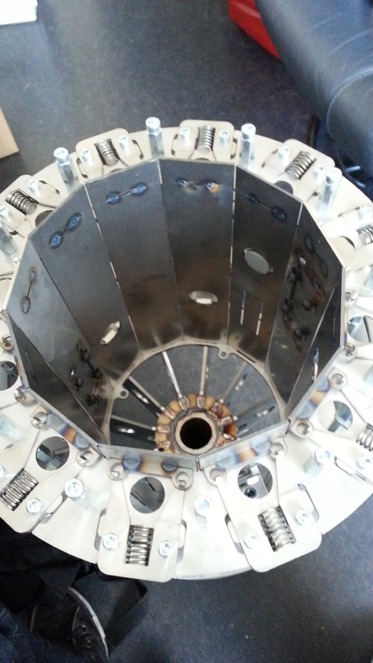

One inch test coupons that is used in thermal spray to test adhesion and they can also be cut to look at the microstructure.

These needs to be positioned as they where a part of the inside wall of the tube/inside bore that are sprayed.

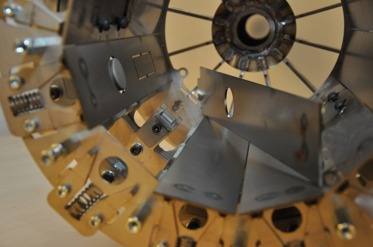

They are held in place in the fixture by twelve small clamps

Overwiev of fixture from "tube/bore-opening"

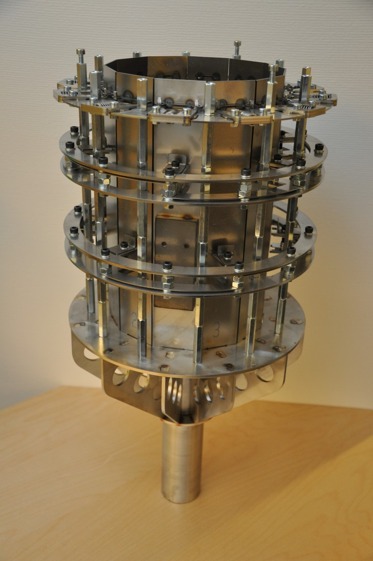

Overwiev of fixture from the side.

The tube wall is then put in place and it is made up out of twelve metal sheet segments with a hole in each for the coupon.

There are special metal sheet segmants with holder for Almen Strip to measure residual stress in the coating.

The bottom of the fixture can be closed, compleatly, 50% and 25% in order to test the effect of dust in the process spraying cavities with a closed or semi closed bottom.

Wall segments are a cheap replaceble part since it will be sprayed on each spray run and this will just add coating each time.

There is also a ring that can be attached to the wall opening. On this one you could weld a tube to make the fixture "deeper" to simulate spraying deeper into a cavity than what the normal fixture will give you.

Tube mounted on the fixture.

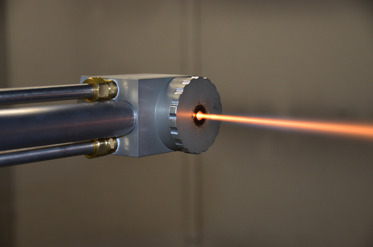

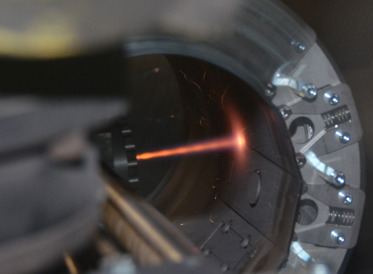

HVAF gun for inside diameter spraying.

HVAF "Hot grit blasting" in the fixture.

HVAF Spraying WC Co Cr in the fixture.